| Availability: | |

|---|---|

| Quantity: | |

|

| |

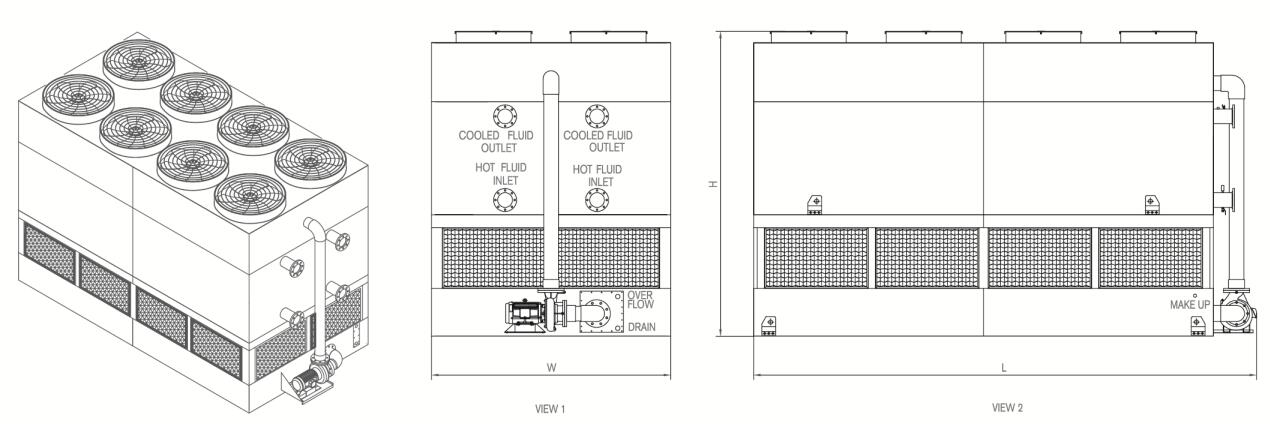

Configurations

STRUCTURE & CASING

The standard enclosure is made of a special type of highly corrosion-resistant steel sheet coated with a composition of Zn+Al(11%)+Mg(3%), and a trace amount of silicon, originally imported from Nippon Steel or Posco. The panels are sheared and folded precisely in whole cold machining process, then densely bolted and sealed for water tightness, with sufficient reinforcing bars, preventing deforming during hoisting process in fields. Each tower is completed with maintenance access and doors of maximized size, for internal inspection convenience. Heat exchange section is firmly supported by frame made in stainless steel, or H.D.G steel plated entirely after welding.

EVAPORATIVE COOLING COILS

The water cooling series adopt high efficient heat exchange coils. Optimized coils has effectively reduced air-side resistance, suitable to work with larger amount of spray water, and significantly improved heat transfer efficiency. The heat exchanger combines one or more coils supported by steel structure, firm and durable.This whole section is of patented design, easy to eliminate cooling medium fluid. Standard coils tube made in stainless steel 304/316, or red copper and titanium ally on option. Different wall thickness can be met on request. Each coil is tested under continuous nitrogen gas pressure of 30 bar for 24 hours, ensure no leaking or weak point, with guarantee provided for 18 for both raw material and design of this critical section of an evaporative cooler.

DIRECT-DRIVE AXIAL FANS

GTM Series adopt highly efficient direct-drive axial fans, fitted with airfoil blades made in high strength resin or al-alloy, coupled and perfectly balanced to a weather proof TEFC three-phase electric motor. The impeller tip speed is suitable to keep the noise level within acceptable limits. Fan cylinder is made in galvanized steel or stainless steel. All parts are durable in heavy duty environment for long service life.

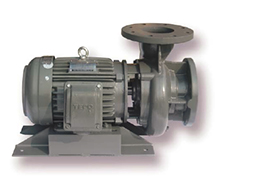

SPRAY PUMP

SPRAY PUMP

Standard spray pumps are of GZ horizontal centrifugal series from GSD brand, with motor of brand TECO, specially designed for evaporative cooling equipments, of generally large flow rate but low pumping head. The selected pumps are of dynamic-static balance, with shaft as an extended section from the motor, for most reliable concentricity. With first grade bearings, the pumps runat minimized vibration and low noise. Mechanicseals avoids abrasion to shaft, no leakage in long term service life. Overload protected on any point of the performance curve, not exceeding the rated power during the whole working period. Enclosure materials and installation arrangement can be optional and modified to suit different projects requirements.

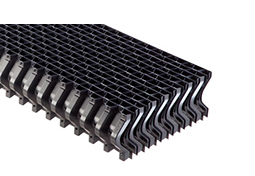

DRIFT ELIMINATOR

Cellular Drift Eliminators are specifically designed to achieve maximum drift removal. With significantly lower pressure drop. The modules are constructed of a series of sinusoidal-shaped, corrugated PVC sheets that are mechanically assembled to mating sinusoidal structural waves, forming closed cells. These cells force the drift droplets being carried in the leaving airstream to make three distinct changes in direction. When the air is forced to change direction, the inertia of the water droplets keeps them moving in a straight line, causing them to impact the wall of the drift eliminator and drain back into the wet section of the tower.

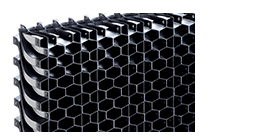

AIR INLET LOUVERS

Cellular air Inlet louvers with advanced design improve air flow into the cooling tower, keep out debris, eliminate water splash-out, which otherwise can cause icing, near-site water damage,and unnecessary water loss. The deign restrict the amount of sunlight into the cooling tower to impede algae growth, reduce noise from the tower, and improve the tower's appearance.

SPRAY PIPE

Spray Pipes made in U-PVC from FPC, of high mechanical strength and long service life, holding pressure1.0 Mpa, accessible to inspect and maintain from outside of the tower, convenient to check with when running fully, completed with buttonholes for quick and tight installations of spray nozzles.

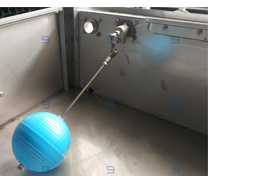

FLOAT VALVE

Valve body casted in S.S 304, of gear type allowing water level adjustment more flexible in a wide range with big angle. Float ball made of ABS with internal polyurethane foam filled, free of leaking concern. The entire float valve system is particularly developed for cooling towers, of long service life.

ANTI-EDDY FILTER

The filter is punched in the same material as the enclosure, highly corrosion resistant. Effectively filtering the sundries, with anti-eddy arrangement, preventing air bubbles sucked into the pumps, to avoid affection on heat exchange of the liquid fluids.

FASTENERS

Fastners of leading brands, standard materials in steel dacromet treated, stainless steel on options. Intensity of fastners is higher than average.

Data Sheet

| Model No. | Nominal Tons | Fan | Spray Pump | Connecting Pipe(mm) | Overall Dimensions(mm) | Weight | |||||||

| Power (kW) | Air Volumn (m3/s) | Power (kW) | Flow Rate (T/h) | Inlet/ Outlet | Make Up | Drainage | L | W | H | Net (kg) | Operation (kg) | ||

| GTM-15 | 6 | 0.55 | 2.4 | 0.75 | 20 | DN50 | DN25 | DN40 | 2200 | 1000 | 1830 | 450 | 700 |

| GTM-110 | 12 | 0.55 | 2.4 | 0.75 | 20 | DN50 | DN25 | DN40 | 2400 | 1000 | 1900 | 490 | 800 |

| GTM-115 | 18 | 0.55×2 | 2.4×2 | 0.75 | 20 | DN65 | DN25 | DN40 | 2300 | 1020 | 1830 | 460 | 1000 |

| GTM-120 | 24 | 0.55×2 | 2.4×2 | 0.75 | 20 | DN65 | DN25 | DN40 | 2300 | 1020 | 1900 | 500 | 1050 |

| GTM-225 | 30 | 0.55×2 | 2.4×2 | 1.5 | 4 | DN80 | DN25 | DN40 | 2860 | 1240 | 2050 | 730 | 1650 |

| GTM-230 | 37 | 1.1×2 | 3.7×2 | 1.5 | 45 | DN80 | DN25 | DN40 | 2860 | 1240 | 2180 | 830 | 1760 |

| GTM-235 | 43 | 1.1×2 | 3.7×2 | 1.5 | 45 | DN65×2 | DN25 | DN40 | 2860 | 1240 | 2420 | 1050 | 2030 |

| GTM-340 | 49 | 1.5×2 | 5.1×2 | 2.2 | 60 | DN65×2 | DN25 | DN40 | 2860 | 1520 | 2440 | 1280 | 2500 |

| GTM-350 | 61 | 1.5×2 | 5.1×2 | 2.2 | 60 | DN80×2 | DN25 | DN40 | 2860 | 1520 | 2630 | 1370 | 2660 |

| GTM-365 | 79 | 1.1×4 | 3.7×4 | 2.2 | 60 | DN80×2 | DN25 | DN40 | 3200 | 1760 | 2630 | 1820 | 3460 |

| GTM-370 | 85 | 1.1×4 | 3.7×4 | 2.2 | 114 | DN80×2 | DN25 | DN40 | 3200 | 2120 | 2750 | 1930 | 3970 |

| GTM-380 | 98 | 1.5×4 | 5.1×4 | 2.2 | 114 | DN80×2 | DN25 | DN40 | 3200 | 2120 | 2750 | 2050 | 4000 |

| GTM-390 | 110 | 1.5×4 | 5.1×4 | 2.2 | 114 | DN80×2 | DN25 | DN40 | 3200 | 2120 | 2750 | 2150 | 4050 |

| GTM-3100 | 122 | 1.5×4 | 5.1×4 | 2.2 | 114 | DN80×2 | DN25 | DN40 | 3550 | 2120 | 2750 | 2330 | 4710 |

| GTM-3110 | 134 | 1.5×6 | 5.1×6 | 2.2 | 114 | DN80×2 | DN25 | DN40 | 4150 | 2120 | 2870 | 2650 | 5550 |

| GTM-5125 | 152 | 1.5×8 | 5.1×8 | 3.7 | 140 | DN100×2 | DN40 | DN40 | 4750 | 2120 | 2970 | 3100 | 6500 |

| GTM-5150 | 183 | 1.5×8 | 5.1×8 | 3.7 | 140 | DN100×2 | DN40 | DN40 | 5050 | 2120 | 3120 | 3500 | 7480 |

| GTM-7175 | 213 | 1.5×8 | 5.1×8 | 5.5 | 160 | DN125×2 | DN40 | DN40 | 5480 | 2120 | 3120 | 3800 | 8240 |

| GTM-7200 | 244 | 1.5×8 | 5.1×8 | 5.5 | 160 | DN125×2 | DN40 | DN40 | 5080 | 2620 | 3120 | 4800 | 9170 |

| GTM-7225 | 274 | 1.5×8 | 5.1×8 | 5.5 | 160 | DN125×2 | DN40 | DN40 | 5480 | 2620 | 3220 | 5600 | 11300 |

| GTM-10250 | 305 | 1.5×10 | 5.1×10 | 7.5 | 240 | DN150×2 | DN40 | DN40 | 6230 | 2620 | 3220 | 6000 | 12560 |

NOTE

Nominal Tons are based upon temp. drop 35~29.5°C/ 95~85°F, WBT 25.5°C/ 78°F, and 0.681 m3/hr/ton.

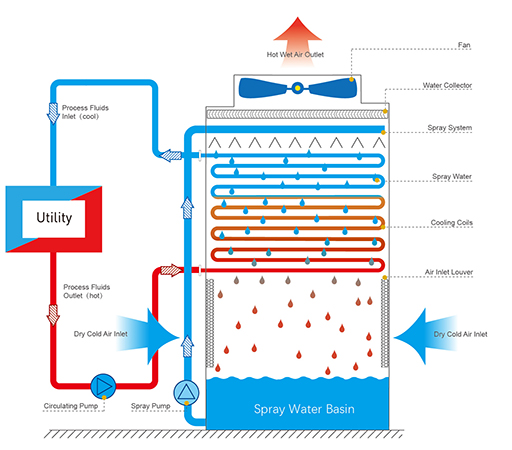

Working Theory

WORKING THEORY

As counter flow towers, the dry cool air is inlet through louvers on both sides of the tower from the bottom, and drawn upwards passing a large heat exchange surface of the coils section under the induced fans, against the spraying water in the opposite way, becoming hot wet air, induced draught out of the tower into the atmosphere by the fans on the top. During this process, a part of the heat from the fluids inside the closed loop is transferred efficiently, and removed to the outside environment.

Features

PRODUCTS ADVANTAGES

Compatible with numerous process fluids

(water, water/glycol, oil, other fluids)

◆ Capable and flexible in customized solutions

◆ Factory assembled for maximal installation convenience

◆ Modular design suits a wide range of heat rejection duties

◆ Compact design with minimal footprints

◆ Multiple corrosion resistant options

◆ Low sound operation options available

◆ More optimizing options available

◆ Performance and quality guaranteed

◆ Super long service life

Certification