| Availability: | |

|---|---|

| Quantity: | |

|

| |

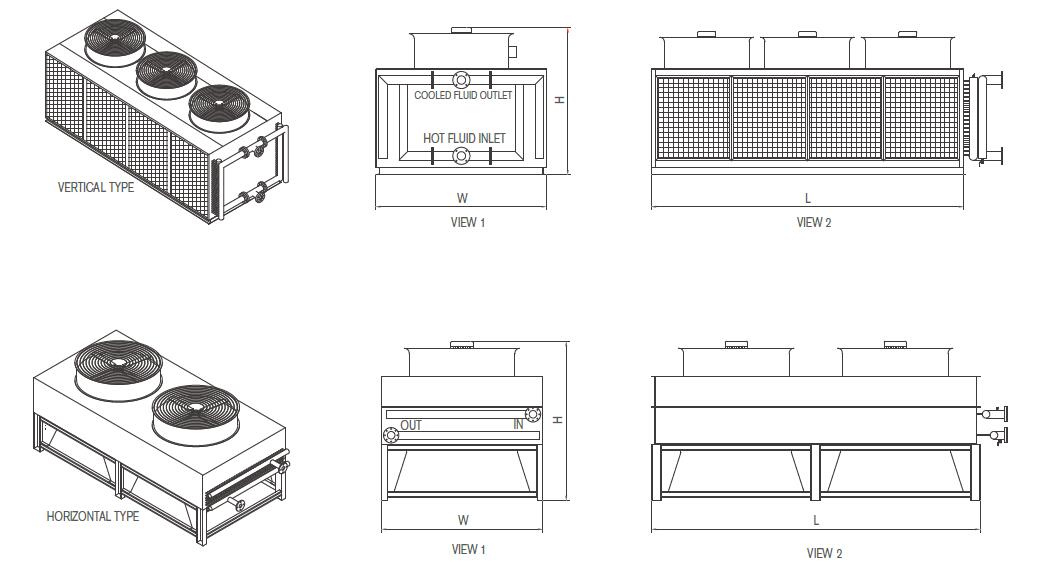

Configurations

STRUCTURE & CASING

STRUCTURE & CASING

The standard enclosure is made of a special type of highly corrosion-resistant steel sheet coated with a composition of Zn+Al(11%)+Mg(3%), and a trace amount of silicon, originally imported from Nippon Steel or Posco. The panels are sheared and folded precisely in whole cold machining process, then densely bolted and sealed for water tightness, with sufficient reinforcing bars, preventing deforming during hoisting process in fields. Each tower is completed with maintenance access and doors of maximized size, for internal inspection convenience. Heat exchange section is firmly supported by frame made in stainless steel, or H.D.G steel plated entirely after welding.

DRY/AIR COOLING COILS

The dedicated dry cooling coils in GKM Series is used exclusively for the purpose of dry cooling, fitted with particularly shaped aluminum or steel fins around the coils tubes, to maximize heat transfer surface and efficiency. The gap between the neighbouring fins can be customized and depends on the environment and other working conditions of the project sites. Dry cooling coils with suitable fin gaps can also work with spray water in cases the temperature drop becomes a challenge in the hot season, and save operation power greatly. Rest of specifications is common to above evaporative cooling coils.

DIRECT-DRIVE AXIAL FANS

The standard closed loop series adopt direct-drive axial fans, fitted with resin or al-alloy airfoil blades perfectly balanced and coupled to a weather proof TEFC three-phases electric motor. The fan casing is a galvanized steel cylinder to draw the air vertically and avoid the risk of recirculation. The tip speed of the impeller is limited to keep the noise level within acceptable limits.

AIR INLET LOUVERS

Cellular air Inlet louvers with advanced design improve air flow into the cooling tower, keep out debris, reduce noise from the tower, and improve the tower's appearance.

FASTENERS

Fastners of leading brands, standard materials in steel dacromet treated, stainless steel on options. Intensity of fastners is higher than average.

Data Sheet

| Model No. | Nominal Tons | Fan | Water Inlet/ Outlet | Overall Dimensions(mm) | Weight (kg) | |||

| Power (kW) | Air Volumn (m3/s) | L | W | H | ||||

| GKM-90H | 16 | 6 | 15 | DN65 | 3200 | 1240 | 2350 | 950 |

| GKM-110H | 20 | 9 | 18.3 | DN65 | 3900 | 1240 | 2350 | 1050 |

| GKM-135H | 25 | 9 | 22.5 | DN65 | 4200 | 1392 | 2350 | 1250 |

| GKM-160H | 30 | 12 | 26.7 | DN65 | 4500 | 1544 | 2350 | 1500 |

| GKM-185H | 35 | 12 | 30.6 | DN65 | 4700 | 1696 | 2350 | 1700 |

| GKM-200V | 40 | 16.5 | 33.3 | DN80 | 4500 | 2200 | 2150 | 2200 |

| GKM-220V | 45 | 16.5 | 36.1 | DN80 | 4500 | 2200 | 2260 | 2500 |

| GKM-250V | 50 | 16.5 | 41.7 | DN80 | 4500 | 2200 | 2420 | 3000 |

| GKM-280V | 55 | 16.5 | 47.2 | DN100 | 5000 | 2200 | 2500 | 3800 |

| GKM-315V | 60 | 22.5 | 52.8 | DN100 | 5000 | 2200 | 2650 | 4300 |

| GKM-355V | 65 | 22.5 | 61.1 | DN100 | 5400 | 2200 | 2650 | 4950 |

| GKM-400V | 75 | 22.5 | 66.7 | DN100 | 5400 | 2200 | 2780 | 5250 |

| GKM-450V | 85 | 30 | 75 | DN100 | 5500 | 2200 | 2920 | 5800 |

| GKM-500V | 94 | 30 | 83.3 | DN100 | 5600 | 2200 | 2800 | 6500 |

NOTE

Nominal Tons are based upon temp. drop 47~41°C/ 117~106°F, DBT 35°C/ 95°F.

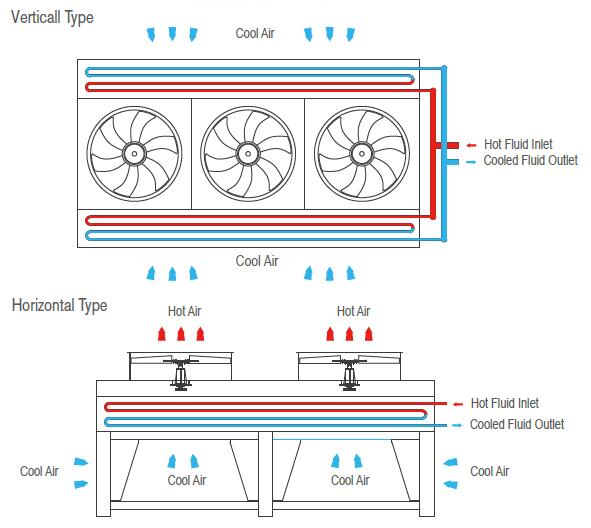

Working Thoery

WORKING THEORY

Dry cooling towers work without spray water. High volume of air is inlet continuously through the louvers, going through the large surface of heat exchange coils with intensive fins. Heat from the process fluid inside the coils is transferred to the high speed flowing air efficiently, and induced draught out of the tower into the atmosphere by the strong fans on the top.

Features

PRODUCTS ADVANTAGES

Compatible with numerous process fluids

(water, water/glycol, oil, other fluids)

◆ Capable and flexible in customized solutions

◆ Factory assembled for maximal installation convenience

◆ Modular design suits a wide range of heat rejection duties

◆ Compact design with minimal footprints

◆ Multiple corrosion resistant options

◆ Low sound operation options available

◆ More optimizing options available

◆ Performance and quality guaranteed

◆ Super long service life

Certification