| Quantity: | |

|---|---|

|

| |

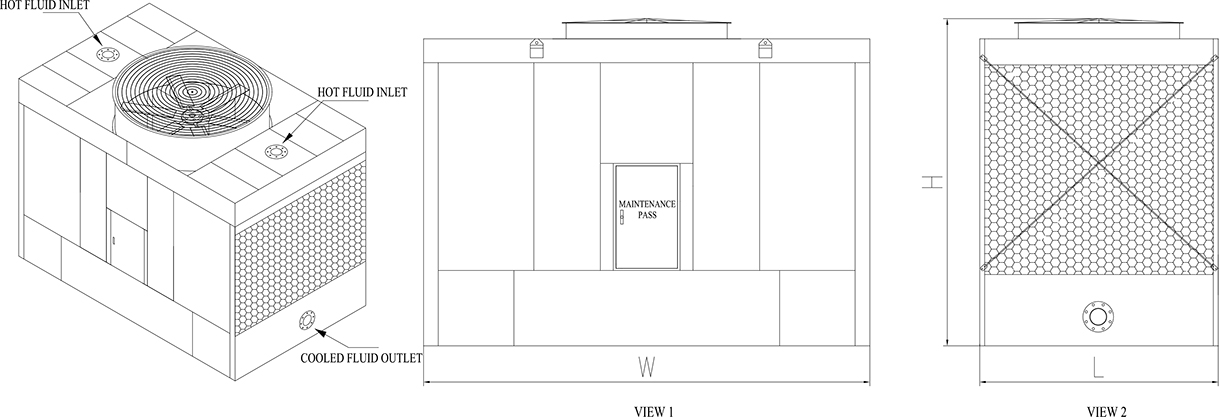

Configurations

STRUCTURE

FRP enclosure with H.D.G supporting frame, strong and wholly of superior corrosion resistance.

Crossflow structure makes maintenance simpler and safer. Large access door allows safer, non-confining and more efficient visual inspections of cold water basin, internal structure, drift eliminators and mechanical system.

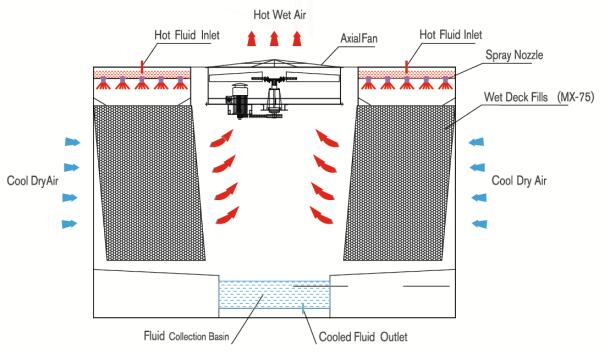

AIR SECTION

High efficient fan with adjustable-pitch blades, specialized motor, and protective guard welded with strong rods H.D.G treated after fabrication. Well designed fan cylinder ensures air go through passing full-area, and of low-turbulence.

WATER DISTRIBUTION SECTION

Thermoformed PVC Film Fill designed to keep circulating water confined to fill area, maximize water contact with airflow, and minimize icing conditions.

High Performance Spiral-Target Nozzles made in PP, durable and designed for easy maintenance and reduced clogging. Gravity-flow distribution allows for easy, nonrestrictive maintenance while operating.

Data Sheet

| Model No. | Nominal Tons | Fan Power (kW) | Connecting Pipe(mm) | Overall Dimensions(mm) | Weight | |||||||

| Inlet | Outlet | Make UP | Overflow | Drain | L | W | H | Operation (kg) | ||||

| GPM0109F | X-1 | 121 | 4 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 1720 | 3250 | 3200 | 1995 |

| V-1 | 139 | 5.5 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 1720 | 3250 | 3200 | 2115 | |

| U-1 | 154 | 7.5 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 1720 | 3250 | 3200 | 2100 | |

| T-1 | 174 | 11 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 1720 | 3250 | 3200 | 2271 | |

| GPM0115F | X-1 | 182 | 4 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 2520 | 3860 | 3300 | 3153 |

| V-1 | 200 | 5.5 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 2520 | 3860 | 3300 | 3099 | |

| U-1 | 220 | 7.5 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 2520 | 3860 | 3300 | 3221 | |

| T-1 | 249 | 11 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 2520 | 3860 | 3300 | 3275 | |

| S-1 | 273 | 15 | DN125×2 | DN150 | DN25 | DN50 | DN50 | 2520 | 3860 | 3300 | 3340 | |

| GPM0120F | V-1 | 221 | 5.5 | DN150×2 | DN200 | DN25 | DN50 | DN50 | 2810 | 4130 | 3500 | 3845 |

| U-1 | 243 | 7.5 | DN150×2 | DN200 | DN25 | DN50 | DN50 | 2810 | 4130 | 3500 | 3889 | |

| T-1 | 286 | 11 | DN150×2 | DN200 | DN25 | DN50 | DN50 | 2810 | 4130 | 3500 | 3952 | |

| S-1 | 317 | 15 | DN150×2 | DN200 | DN25 | DN50 | DN50 | 2810 | 4130 | 3500 | 4093 | |

| R-1 | 383 | 18.5 | DN200×2 | DN250 | DN25 | DN65 | DN50 | 2810 | 4130 | 3500 | 4395 | |

| Q-1 | 412 | 22 | DN200×2 | DN250 | DN25 | DN65 | DN50 | 2810 | 4130 | 3500 | 4536 | |

| P-1 | 460 | 30 | DN200×2 | DN250 | DN25 | DN65 | DN50 | 2810 | 4130 | 3500 | 4818 | |

| GPM0215F | V-1 | 264 | 5.5 | DN150×2 | DN200 | DN40 | DN65 | DN50 | 3480 | 4500 | 3550 | 4918 |

| U-1 | 304 | 7.5 | DN150×2 | DN200 | DN40 | DN65 | DN50 | 3480 | 4500 | 3550 | 5014 | |

| T-1 | 337 | 11 | DN150×2 | DN200 | DN40 | DN65 | DN50 | 3480 | 4500 | 3550 | 5062 | |

| S-1 | 372 | 15 | DN150×2 | DN250 | DN40 | DN65 | DN50 | 3480 | 4500 | 3550 | 5259 | |

| R-1 | 433 | 18.5 | DN200×2 | DN250 | DN40 | DN65 | DN50 | 3480 | 4500 | 3550 | 5653 | |

| Q-1 | 462 | 22 | DN200×2 | DN250 | DN40 | DN65 | DN50 | 3480 | 4500 | 3550 | 5844 | |

| P-1 | 486 | 30 | DN200×2 | DN250 | DN40 | DN65 | DN50 | 3480 | 4500 | 3550 | 6035 | |

NOTE

Nominal Tons are based upon temp.drop 35~29.5°C/ 95~85°F, WBT 25.5°C/ 78°F, and 0.681 m3/hr/ton.

Working Thoery

WORKING THEORY

In GPM open cooling towers, the hot water is inlet to the water distribution basin on the top of the tower firstly, and spread onto the extensive surface of the wet deck fills after flowing through the spreading holes by gravity. Meanwhile the dry cool air is inlet through the side louvers of the tower, passing the fills across the water falls. During this process, a part of water is evaporated, with heat removed. The wet hot air is induced draught out of the tower into the atmosphere by the fans on the top, while the cooled water is collected back to the bottom collection basin with the eliminator, flowing back to the equipment requiring cooling water.

Features

PRODUCTS ADVANTAGES

◆ Long Service Life

Corrosion-resistant materials such as H.D.G steel for structure, and FRP for enclosure, ensure the towers durability running with heavy duty in all sorts of enviroment for long years.

◆ Vibration Resistant

GPM towers are designed with strong and firm structure for best control of vibration levels, to avoid impacting the towers's running efficiency and stability.

◆ Low Operation Cost

With high-efficiency fill and fans, gravity-flow water distribution and active spray nozzles, and optimized driving systems, the GPM series cooling towers have achieved highest cooling efficiency with lowest power consumption.

◆ Noise Level Controlled

GPM Towers can be equipped with low sound fans, in combination with no-splash crossflow film-fill, to meet most of noise limitations in different area.

◆ Strong Weather Adaptability

From hot to icy cold seasons, and other time in between, GPM cooling towers are made to meet very different install and working environment globally, with minimal maintenance requirements.

◆ Other Features

-Modular design suits a wide range of heat rejection duties

-Compact design demanding minimal footprints

-More optimizing options available

-Performance and quality guaranteed